STP Fails When Designed with BOD

Why Sewage Treatment Plants Fail When Designed Only on BOD

Many sewage treatment plants (STPs) fail to consistently meet discharge norms despite being designed to accepted standards. In most cases, these failures are not caused by poor construction or lack of operation, but by limitations in the design basis itself.

A recurring root cause is the continued use of Biochemical Oxygen Demand (BOD₅) as the primary and sometimes sole design parameter for biological treatment systems.

While BOD remains a mandatory compliance parameter under norms prescribed by the Central Pollution Control Board (CPCB), relying on BOD alone for biological and aeration design has led to widespread underperformance—particularly in modern, compact, and modular STPs.

👉 For a detailed explanation of how wastewater organics behave biologically, refer to our article:

What BOD Represents — and Its Design Limitation

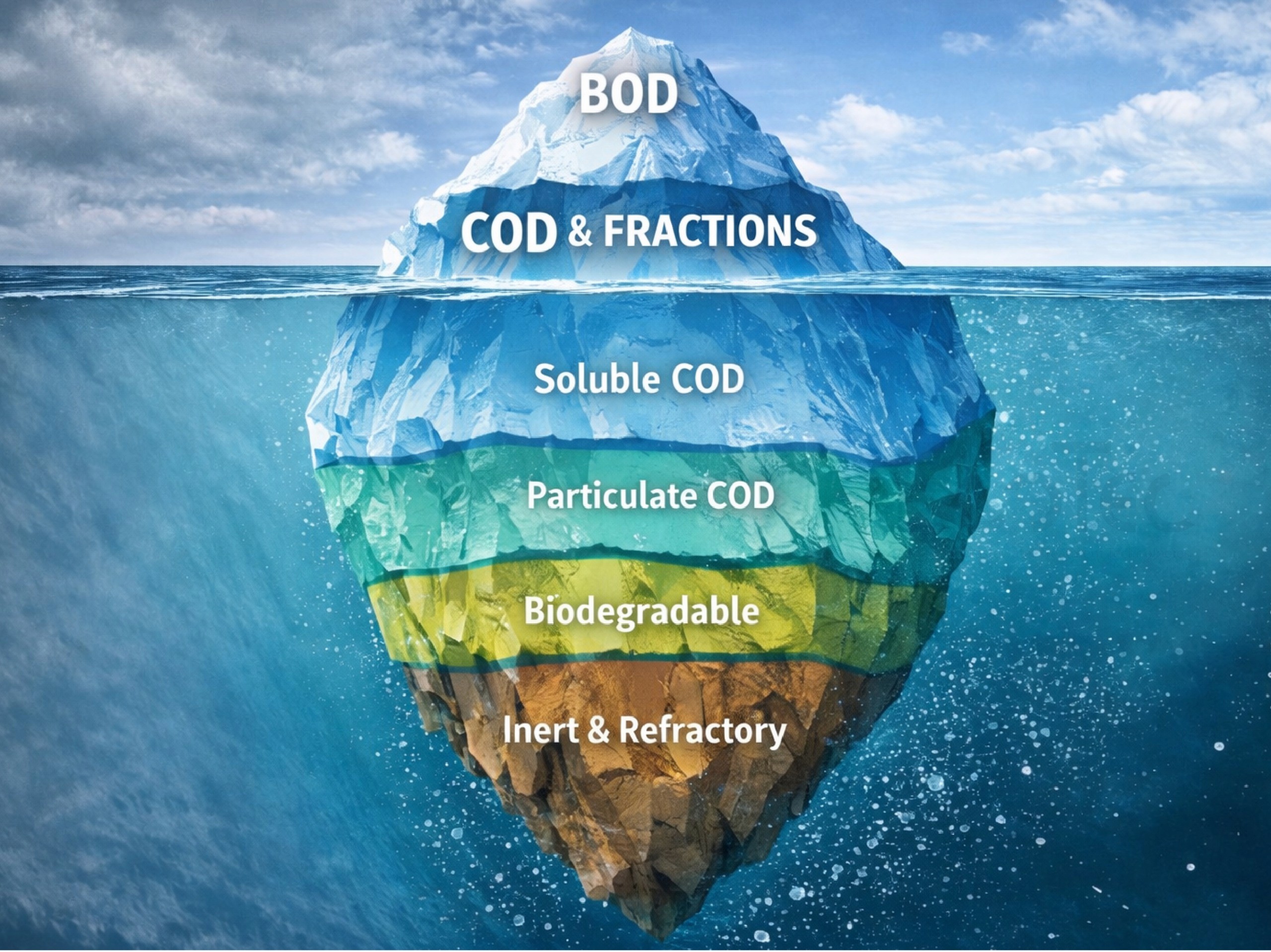

BOD₅ measures the oxygen demand exerted by biodegradable organic matter over a fixed five-day laboratory test. It provides a single aggregated value that indicates pollution strength but does not describe biological kinetics.

The oxygen demand associated with slowly biodegradable and inert COD

As a result, BOD describes compliance potential, not process behaviour.

Oxygen Demand Mismatch Embedded in BOD-Only Design

One of the most critical consequences of BOD-only design is incorrect aeration sizing.

Once constructed, this mismatch cannot be corrected operationally.

👉 This mismatch is explained in detail in the companion article:

Under-Aeration Is a Design Outcome, Not an Operational Issue

In most Indian STPs:

Blower capacity, diffuser density, and aeration rates are fixed at design

Operators have limited ability to modify oxygen supply meaningfully

When BOD alone is used for aeration design:

Oxygen demand from slowly biodegradable COD is underestimated

Hydrolysis of particulate COD becomes rate-limiting

Nitrification remains incomplete or unstable

Biomass quality degrades over time

This results in:

Persistent effluent COD and ammonia exceedances

Poor sludge settleability

Increasing suspended solids in treated water

These outcomes occur even when the plant is operated as intended.

Disproportionate Aeration and Inefficient Energy Use

BOD-based design also fails to address when and where oxygen is required within the biological process.

Without COD fractionation:

Oxygen may be supplied continuously, regardless of substrate availability

Critical phases requiring oxygen are under-supported

Anoxic conditions required for nitrogen removal are unintentionally eliminated

The result is:

Continuous energy consumption

Biologically inefficient oxygen utilisation

No consistent improvement in compliance performance

This leads to energy use without performance alignment.

Why Nitrogen Removal Commonly Fails in BOD-Designed STPs

Biological nitrogen removal depends on readily biodegradable carbon being available at the correct time.

BOD does not indicate:

How much carbon is readily available

How much carbon is readily available

If external carbon will be required

Consequently:

Denitrification becomes unreliable

Ammonia and nitrate persist in treated effluent

Compliance depends on favourable influent conditions rather than robust design

👉 The role of rbCOD and sbCOD in nitrogen removal is explained in:

“Beyond BOD: Why COD Fractionation Is Essential for Modern CPCB-Compliant STP Design.”

Why These Failures Are Common Under Indian Conditions

Indian sewage typically contains:

High suspended and particulate organic matter

Significant inert COD fractions

Wide daily and seasonal variability

Under these conditions, BOD-only design:

Overestimates biological reaction rates

Underestimates sludge generation

Misrepresents long-term oxygen demand

This explains why many STPs perform acceptably during initial operation but deteriorate over time.

Compliance Parameters vs Design Parameters

It is essential to distinguish between:

Regulatory parameters (what CPCB measures)

Design parameters (what biological systems respond to)

Using BOD beyond its intended role creates systemic design risk.

Sewage treatment plants do not fail because BOD is irrelevant.

They fail because BOD is incomplete when used as the sole design basis.

When BOD alone governs design:

Oxygen demand is underestimated

Aeration is biologically mismatched

Nitrogen removal becomes unreliable

Energy efficiency and compliance are both compromised

For modern, CPCB-compliant STPs—especially modular and decentralised systems—process-based design using COD fractionation is essential.