Understanding MBR Technology in the Indian Sewage Treatment Context

Misrepresentation, Practical Risks, and Global Lessons

With the tightening of sewage discharge and reuse norms in India, advanced treatment technologies such as Membrane Bioreactors (MBRs) are increasingly being considered for municipal, institutional, and commercial sewage treatment applications. While MBR is a proven technology with established global performance, its effectiveness is strongly dependent on appropriate design, correct process integration, and sustained operational discipline.

In the Indian context, instances have been observed where systems described as MBR do not conform to the fundamental process requirements of integrated biological treatment and membrane-based solid–liquid separation. In addition, operational aspects such as influent variability, energy consumption, membrane fouling, chemical cleaning requirements, and skilled manpower availability are often inadequately addressed at the planning and procurement stages. These factors have, in certain cases, resulted in performance degradation, increased lifecycle costs, and modification or abandonment of membrane-based systems.

A lifecycle-based and process-oriented evaluation of advanced treatment systems is essential to ensure sustained regulatory compliance, operational reliability, and responsible public and private investment in sewage treatment infrastructure.

What MBR Is Designed to Achieve

A Membrane Bioreactor (MBR) is an advanced sewage treatment process that integrates conventional biological treatment with membrane-based solid–liquid separation. In a true MBR system, microfiltration or ultrafiltration membranes act as the primary barrier between treated water and biomass. The technology is designed to deliver consistently low suspended solids, high pathogen removal, and reuse-grade treated water, while allowing operation at higher mixed liquor concentrations and reduced plant footprint. When correctly applied, MBR is particularly effective in space-constrained urban developments and high-value water reuse applications.

How MBR Is Misrepresented in the Indian Market

In the Indian context, MBR is frequently misunderstood and misrepresented due to the absence of clear process-level regulation. In a MBR, the membranes are fully integrated into the biological reactor, and process performance depends on controlled sludge age, mixed liquor concentration, membrane flux, and transmembrane pressure. When membranes are merely added as a polishing step, the system lacks the biological and hydraulic integration necessary for stable long-term performance.

Another area of misrepresentation arises from the way operation and maintenance requirements are communicated. MBR systems are sometimes positioned as fully automatic and low-skill solutions. In reality, MBR is a precision-driven process that demands trained operators, strict preventive maintenance routines, and continuous monitoring of key parameters such as dissolved oxygen, membrane fouling rates, and cleaning cycles. When this operational complexity is not acknowledged at the procurement stage, plants often face performance challenges after commissioning.

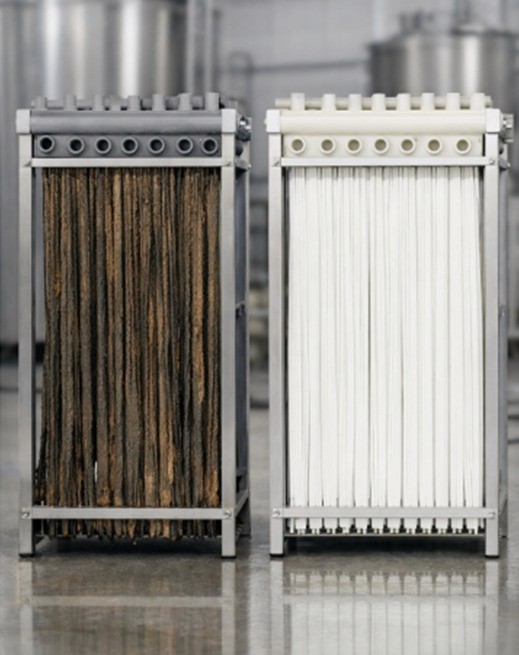

Misrepresentation is further amplified by the way effluent guarantees are offered without adequate consideration of influent variability. Indian sewage characteristics are often inconsistent, with fluctuations in organic load, oil and grease, detergents, and occasional industrial discharges. Many MBR systems are designed assuming stable influent quality and are installed without sufficient pre-treatment or equalization. Under such conditions, membrane fouling accelerates, cleaning frequency increases, and membrane life reduces significantly, leading to higher operating costs and loss of reliability.

Commercial pressures also contribute to misrepresentation. In competitive tenders, MBR systems are often value-engineered to reduce capital cost by minimizing membrane area, aeration capacity, and redundancy. While these measures may improve price competitiveness, they push the system to operate at higher fluxes and lower safety margins, increasing long-term operational risk. The consequence is that the technology is perceived as unreliable, even though the root cause lies in design and procurement decisions rather than the process itself.

Why Some MBR Plants Have Been Dismantled or Converted Globally

Globally, MBR technology has been widely adopted and continues to operate successfully in many regions. However, there have also been instances where MBR plants were dismantled, converted, or simplified. These outcomes were generally driven by contextual and economic factors rather than fundamental technological failure.

In parts of Europe and the Middle East, early municipal MBR installations experienced challenges related to high energy consumption. Continuous aeration is required both for biological treatment and for membrane scouring, and in regions with high power tariffs, lifecycle operating costs exceeded initial projections. In such cases, some utilities chose to revert to conventional activated sludge systems with tertiary filtration to balance compliance with energy efficiency.

In several Asian markets, including parts of China and India, membrane fouling and early replacement emerged as major issues. These problems were typically linked to inadequate influent control, poor pre-treatment, and limited operator expertise. When membrane replacement costs became economically unviable after the warranty period, some operators chose to remove the membranes and continue operation as conventional biological plants, effectively abandoning the MBR configuration.

A recurring global challenge has been the dependence of MBR systems on skilled operation. In regions where trained manpower was not consistently available, maintenance became reactive rather than preventive. Rising transmembrane pressure, reduced flux, and frequent downtime eventually led operators to bypass or dismantle membrane systems to maintain basic plant functionality.

There are also documented cases, particularly in Australia and parts of Europe, where MBR was installed in applications that did not require reuse-grade water. In such scenarios, conventional biological nutrient removal systems could have met discharge standards at significantly lower lifecycle cost. Over time, these plants were simplified or retrofitted to less complex processes, highlighting the risk of over-engineering rather than a failure of MBR technology itself.

Key Considerations for Indian Builders, Regulators, and Procurement Teams

The relevance of MBR should be assessed primarily against the requirement for high-quality treated water and long-term reuse. The technology offers clear advantages where space is limited and reuse standards are stringent, but it must be evaluated over a 10–15 year lifecycle horizon rather than on initial capital cost alone. For regulatory authorities, it is important to recognize that short-term effluent compliance does not always reflect long-term process sustainability. Stable performance depends on influent management, operator capability, and design integrity, all of which are not visible through snapshot sampling alone. For procurement personnel, clarity is essential in distinguishing between true integrated MBR systems and membrane-polishing configurations, understanding realistic membrane life expectations under Indian conditions, and assessing long-term energy and chemical consumption commitments.

Broader Industry Insight

The experience with MBR in India mirrors a broader trend seen with other sewage treatment technologies, where systems are selected primarily to demonstrate compliance rather than to ensure long-term resilience. When technologies are evaluated only on immediate output quality and capital cost, the risk of operational stress and eventual abandonment increases. This challenge underscores the need for greater transparency in technology selection, clearer communication of limitations, and a stronger focus on lifecycle performance.

Advanced treatment technologies such as MBR are powerful and proven when applied in the right context with appropriate design discipline and operational support. Where they underperform, the cause is rarely the technology itself, but rather a mismatch between design intent, real-world conditions, and long-term operational expectations. A more informed, process-oriented approach to selection and regulation can ensure that such technologies deliver their intended benefits sustainably over time.